Determining the distortion of 3D printed polypropylene objects as a function of radiation grafting degree and developing a predictive method to counteract the distortion

Willaim Leising1,2.

1Department of Chemistry, The university of Manchester, Manchester, United Kingdom; 2Dalton Cumbrian Facility, Dalton nuclear institute, Manchester, United Kingdom

Introduction and objectives

Additive manufacturing (AM) is a well-established technique, however, there are many potential advancements and new application areas remaining to be explored.1 To the best of our knowledge, no research has been conducted into the radiation grafting of AM parts.

The objective of this study was to successfully graft 3D printed architectures and obtain novel knowledge on the effects of radiation grafting to AM parts.

Findings

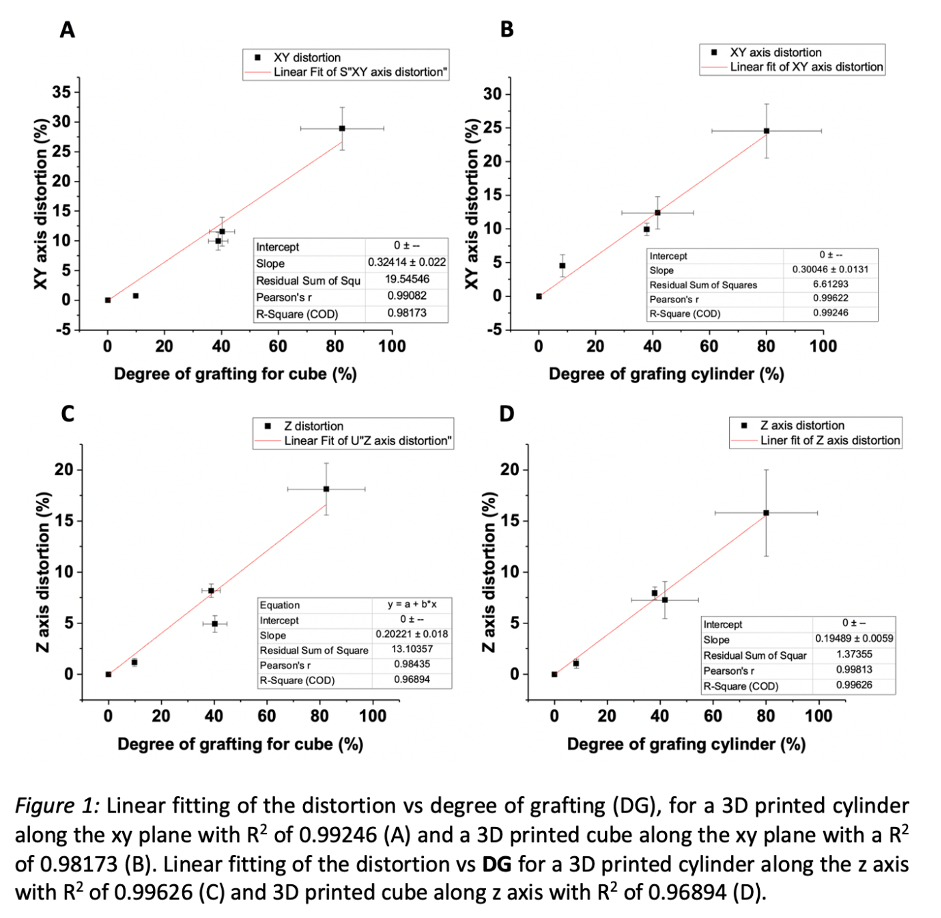

This goal was achieved by using radiation grafting of acrylic acid onto polypropylene.2 Upon grafting, 3D object distortion and increase in size was observed. These phenomena were determined to be caused by the internal grafting. The increase in size was found to be linear with respect to the Degree of Grafting (DG), with greater distortion in the xy plane compared to the distortion along the z axis (Figure 1).

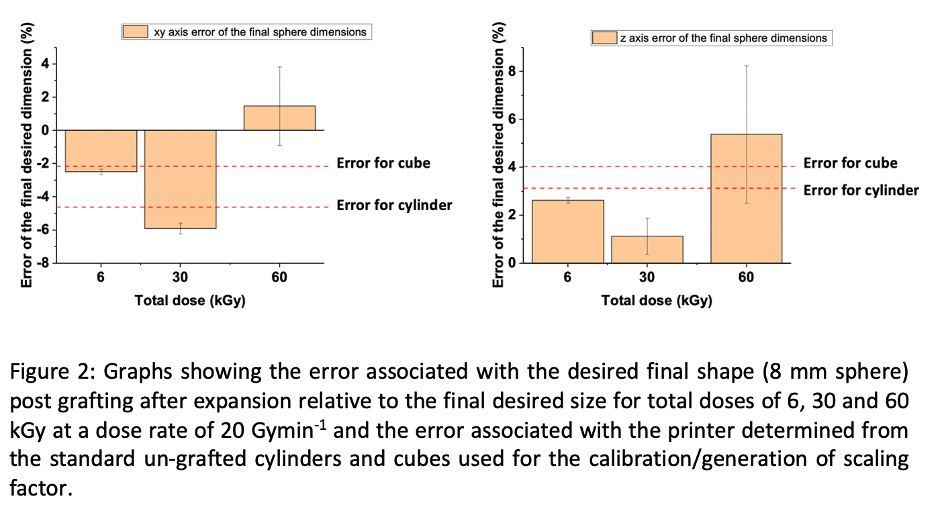

Obtained data was used to generate scaling factors for varying doses that would allow for the grafted object to be of the desired size. We have shown that the use of scaling is effective, with the error associated with the final size being less than or comparable to a standard 3D printed part (Figure 2).

Conclusion

In this work, we have presented a showcase of successful radiation grafting of AM parts and demonstrated that the distortion caused by grafting can be overcome through the application of scaling factors.

References

1 W. Gao, Y. Zhang, D. Ramanujan, K. Ramani, Y. Chen, C. B. Williams, C. C. L. Wang, Y. C. Shin, S. Zhang and P. D. Zavattieri, Computer-Aided Design, 2015, 69, 65–89.

2 A. Ashfaq, M. C. Clochard, X. Coqueret, C. Dispenza, M. S. Driscoll, P. Ulański and M. Al-Sheikhly, Polymers 2020, Vol. 12, Page 2877, 2020, 12, 2877.