Xray solutions for phytosanitary applications with economic and process performance details

Cody Wilson1, Jeremy Brison1, Francois De Diesbach1, Mauro Ferreira1, Damien Prieels1, Frederic Stichelbaut1, Frederic Dessy1, Arnaud Pierard1, Dominique Vincent1.

1IBA s.a., Louvain-la-Neuve, Belgium

Phytosanitary treatment using radiation is an emerging market. Commercial e-beam and gamma centers have been in operation for decades. More recently, high power X-ray centers have seen increased demand for phytosanitary use. X-Ray irradiation is a natural match for the widely varying product density encountered in phytosanitary applications, though challenges to widescale adoption remain.

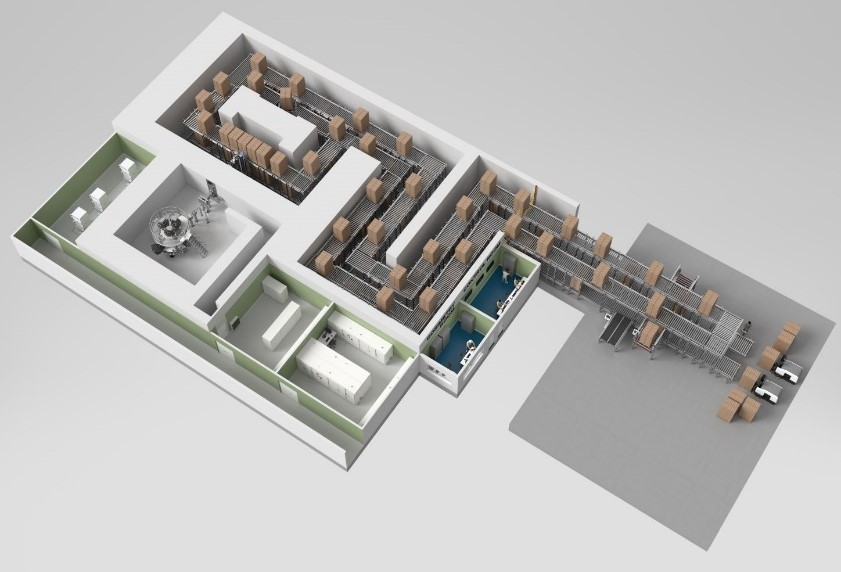

Demand for medical device sterilization has led manufacturers and early users to deliver roadmaps to make X-Ray processing an efficient and reliable industrial process. Accelerators have been made more efficient, simpler to use, and more reliable. These accelerators serve as the enabling technology and have been integrated with state-of-the art conveying and automation devices, driven by modern Process Control Systems. This second generation of X-Ray irradiators is now being deployed all around the world and demonstrate remarkable performance [1].

In this paper we detail the system performance of industrial X-ray product offering of IBA known as Be Wide. Business case info from commercial, governmental, and academic collaborators is used to detail economic considerations. System performance relative to E-beam and Gamma processing is detailed in this paper. Special attention is given to process bottlenecks, including de-palletization and handling of consolidated products appropriate for treatment in each modality. A marked increase in economic viability is observed when a maximum treatment energy of 7 MeV is permitted. Many international markets limit treatment energy to 5 MeV, presenting a hurdle to adoption.

[1] Steris, 2022, X-ray Sterilization Facility in Venlo, The Netherlands | STERIS ASThttps://www.youtube.com/watch?v=rdR71u6wTYA