Head of Research Group Electron-Induced Material Modification

Dept. Processing Technology

Leibniz Institute of Polymer Research Dresden

Continuous electron-induced reactive processing – a sustainable reactive processing method

Michael Müller1, Carsten Zschech1, Mathias Pech2, Ines Kühnert1, Udo Wagenknecht2, Sven Wießner1.

1Dept. Processing Technology, Leibniz Institute of Polymer Research Dresden, Dresden, Germany; 2Leibniz Institute of Polymer Research Dresden, Dresden, Germany

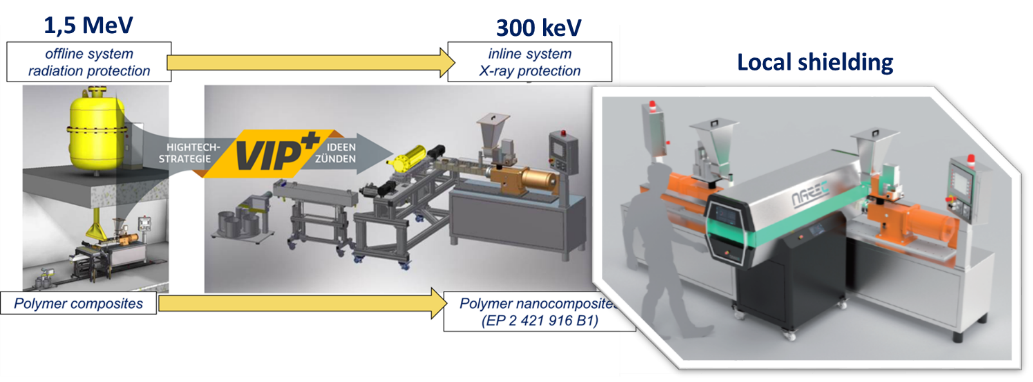

In order to fulfil requirements of property level for different applications, various methods of physical and chemical modification of polymers are used. In the field of melt-compounding, reactive processing is commonly used since this approach combines the possibility to modify the polymer in a physical and chemical way. In typical state-of-the-art reactive processing, the chemical reaction is induced by temperature-sensitive initiator decay, whereby it is difficult to precisely control the desired chemical reaction and handle the resulting viscosity change. In contrast to such conventional reactive melt processing, the electron beam technology is able to induce polymer chemical reactions by a spatial and temporal precise input of electron energy. Based on these advantages, the electron-induced reactive processing (EIReP) was developed. This novel temperature-sensitive melt processing method was successfully tested for different polymer compounds. The outcomes prove that EIReP offers a novel approach for preparing various high-performance polymeric materials without using temperature-sensitive initiators or chemical additives. The scale-up to a continuous running inline demonstrator using a 300 keV electron emitter is implemented for the very first time.

Figure 1 Scheme for the technical implementation to an inline-system

Lectures by Michael T. Müller

| When | Session | Talk Title | Room |

|---|---|---|---|

|

Mon-07 15:30 - 17:30 |

Plenary 4: Advanced polymers | Continuous electron-induced reactive processing: A sustainable reactive processing method | Lunar & Moon |